Green Manufacturing

Green Manufacturing

Edison Opto Group is gradually introducing information-based intelligent factories and actively transforming towards smart manufacturing. Automated equipment is being introduced into the production process. Through low-carbon processes and intelligent energy-saving technologies, while ensuring product quality, energy efficiency is simultaneously improved to reduce costs and save energy, minimizing the negative environmental impact during operations. To achieve low-carbon processes, each plant actively promotes various energy-saving measures, including tooling improvements, process optimization, production control, work-hour adjustments, replacement of old chillers, etc. Specific measures are as follows:

Introduction of Information-Based Smart Factory Architecture

Through iMES, implementation has been gradually introduced across all plants, including work order reporting, process management, material identification, equipment management, and quality management. Combined with the existing ERP system, information integration achieves intelligent management and transformation into smart manufacturing.

Information-Based Smart Factory Architecture

Introduction of Automated Equipment and Low-Carbon Process Optimization

Edison Opto has introduced automated equipment and energy-saving process technologies to improve production efficiency while ensuring quality, reducing manual process losses, and thereby achieving a more energy-efficient and efficient manufacturing process, promoting the green transformation of production processes. Automation requirements are incorporated into the product development and design stage, ensuring structural design and parts selection are suitable for automated production lines. The results introduced in 2024 are as follows:

(1) Edison - Litek Opto Zhonghe Plant:

Automated assembly line for finished automotive lighting products was introduced, increasing average daily production capacity by nearly 48% in 2024.

(2) Edison Opto Dongguan Plant:

Automated assembly line for panel lights was introduced, increasing average daily production capacity by nearly 74% in 2024, with manpower reduced by 31%.

(3) Low-carbon and energy-saving process optimization in each plant:

To achieve low-carbon processes, various energy-saving measures have been actively implemented, including tooling improvements, process optimization, production control, and work-hour improvements. Taking the Zhonghe Plant as an example:

A. Optimization of die bonding and wire bonding machine parameters increased stability, improving man-to-machine ratio by 50%.

B. Modification of existing automatic testing equipment increased the number of testable models from 2 to 4, reducing manual testing operations, with efficiency improved by 400% compared to manual testing.

C. Module depaneling changed from manual breaking to semi-automatic equipment, improving efficiency by 300%.

D. For final product fastening at the high-torque 85 kgf/cm station, auxiliary jigs (rotary assist arms) were introduced, reducing operator burden and improving production efficiency by 100%.

E. Automatic solder feeder was introduced at wire bonding stations, improving soldering efficiency by 45%.

Low-Carbon Equipment Investment – Chillers and Air Compressors

(1) Edison Opto Headquarters Zhonghe Plant

Air-conditioning equipment is mainly used to maintain constant temperature and humidity in production areas, ensuring long-term stable operation of production equipment. In 2024, Edison Headquarters and the Zhonghe Plant replaced a total of 8 chillers and added 4 chiller timer switches, saving approximately 182,000 kWh of electricity.

(2) Yangzhou Edison Opto Plant

A. Air-Conditioning Energy-Saving System Upgrade:

Through intelligent transformation and application of high-efficiency technologies, both energy consumption and carbon emissions were reduced. In 2024, cumulative electricity savings were 568,000 kWh, with annual carbon reduction of 371.6 tons of CO₂.

Magnetic levitation centrifugal chiller: frictionless operation, reducing energy consumption by over 30% compared to traditional units.

Intelligent variable frequency system: dynamically adjusts pump flow to match load demand.

Low-resistance piping optimization: reduces transmission energy consumption and improves overall system efficiency.

AI energy efficiency management platform: predicts loads based on big data and automatically optimizes operating parameters.

B. Air Compressor Energy-Saving System Upgrade:

Through intelligent transformation and equipment upgrades, both energy consumption and carbon emissions were reduced. In 2024, electricity savings totaled 175,000 kWh, reducing CO₂ emissions by 114.5 tons.

Dual-stage compression permanent magnet variable frequency air compressors, saving over 30% compared to traditional equipment.

Low-resistance piping and high-efficiency filtration system to reduce pressure loss and energy consumption.

Upgraded refrigerated dryers to improve air quality while reducing operational load.

Intelligent control system for the air compressor station to optimize equipment combinations and parameters in real time.

Remote management platform for precise pressure fluctuation control.

Fully unmanned operation at the station, improving operation and maintenance efficiency by 50%.

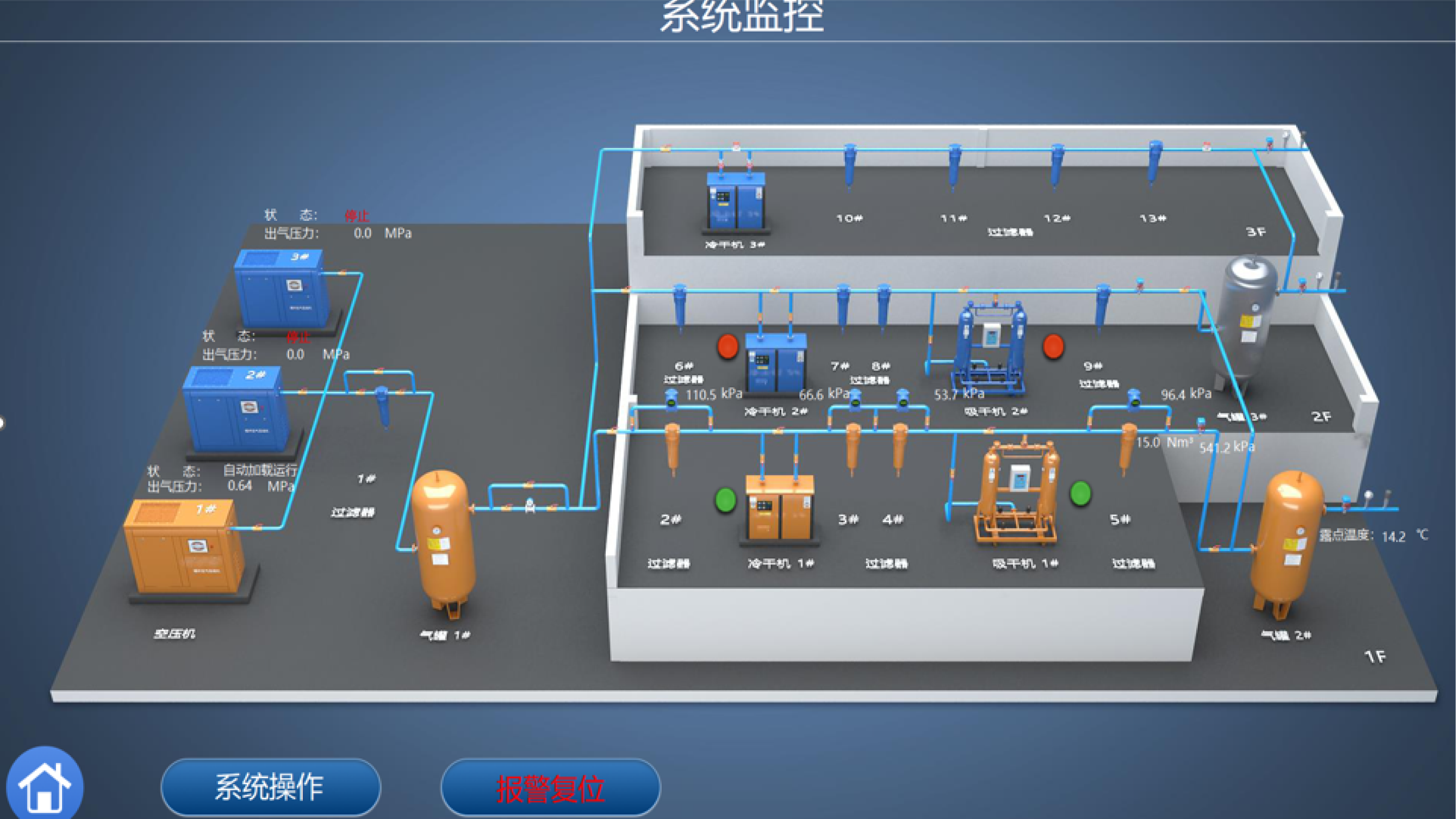

Air Compressor System Monitoring Diagram

Yangzhou Plant Photovoltaic Power Generation

The plant implemented a 0.87MW photovoltaic power generation project, with annual power generation in 2024 increasing by approximately 780,000 kWh compared with 2023, saving about 832,000 kWh.

Rooftop Photovoltaic Power Generation Aerial View

Energy-Saving Information Data Center

To improve the power efficiency of the information data center, Edison Headquarter adopts server virtualization, installed forced exhaust ducting in the data center air-conditioning exhaust room, and implemented constant temperature control to reduce power consumption. In 2024, the total annual electricity consumption of the data center decreased by 39,500 kWh compared with 2023, a reduction of approximately 19%.

| Energy-Saving Themes | Content | 2024 Achievements |

|---|---|---|

| Server Virtualization | Consolidated services from old servers to the virtual server platform to reduce energy consumption of physical machines. | Consolidated MES system and other information services in the Taipei plant, reducing the demand for new server procurement. |

| Installation of Forced Exhaust Ducts in the Data Center Air-Conditioning Exhaust Room | The exhaust ducts of the computer room air conditioner (CRAC) outdoor units are connected directly to the building’s exhaust outlets through newly installed piping, improving the heat dissipation efficiency of the outdoor units. | Construction has been completed and implemented in the Taipei Headquarter data center. |

| Constant Temperature Control | Introduced constant temperature control in the data center air-conditioning system to reduce energy waste. | Achieved stable data center temperature through dual-air-conditioning redundancy and alternating use with the building’s air-conditioning system, while reducing abnormal conditions. |